From Sketch to Hand-over: A Renovation Journey Reinvented

Today we explore “Digital Tools for End-to-End Renovations: Leveraging 3D Modeling and BIM from Concept to Completion,” showing how integrated models, common data environments, and collaborative workflows transform renovations, reduce risk, reveal hidden constraints, engage clients earlier, streamline decisions, and help teams deliver beautifully coordinated spaces with fewer surprises and measurable savings from the very first sketch through long-term operations. Share your questions and subscribe for deep dives and hands-on guides.

Seeing What Exists: Reality Capture That Tells the Truth

A laser scanner sweeps the space with millions of measurements, stitching together a high-fidelity point cloud that preserves reality with millimeter-level precision. From this, modelers trace walls, beams, pipes, and quirky deviations that matter later. Instead of guessing, everyone references the same quantitative truth. When surveyed data flows into the modeling environment quickly, design iterations accelerate, and confidence grows because decisions rest on evidence rather than assumptions and rushed site notes scribbled in dim corridors.

Transforming raw scans into a clean, usable model requires disciplined workflows: alignment of scans to known control, careful segmentation, and adherence to modeling standards that reflect required levels of development. The process is not glamorous, yet it pays dividends when drawings read consistently and downstream trades know exactly what is real. Set naming conventions early, document assumptions clearly, and publish the model on a schedule. Reliability becomes habit, and stakeholders stop hedging against uncertainty with unnecessary contingencies.

On a historic retrofit, scans revealed a concealed duct sleeve that narrowed a corridor by just forty millimeters—enough to violate accessibility. Catching it before demolition allowed a simple soffit compromise instead of rebuilding an entire wall sequence. The avoided rework paid for the scanning program ten times over. Sharing findings with photos, annotated slices, and a short video helped non-technical decision makers feel the evidence, approve a practical fix quickly, and keep the schedule intact without drama.

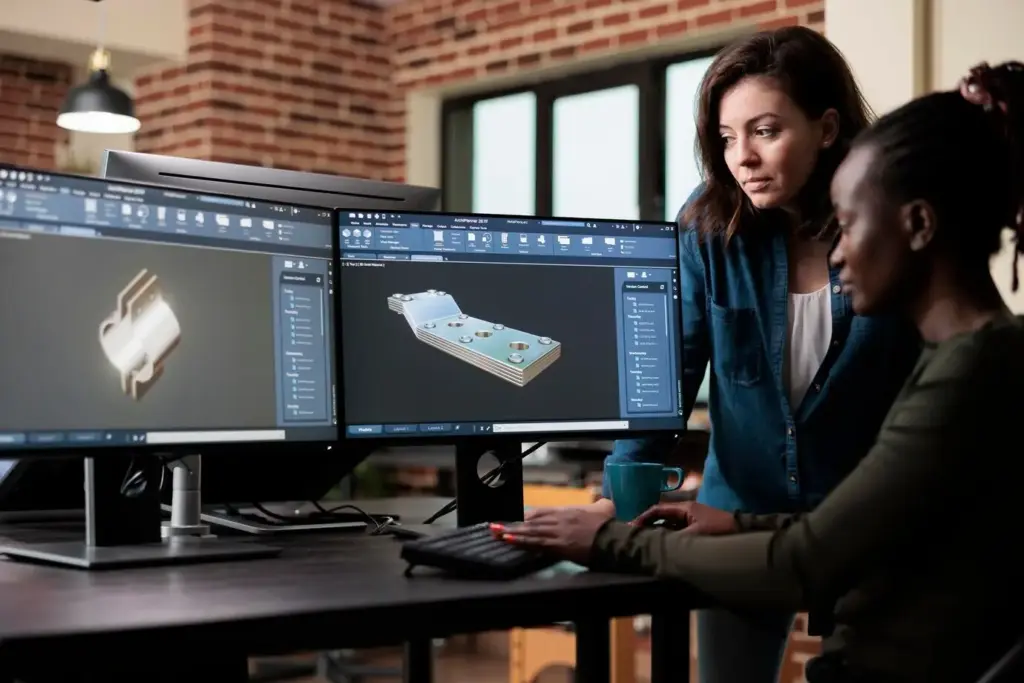

Design Options that Speak for Themselves

Concept development thrives when ideas become immersive experiences rather than static drawings. By modeling alternatives quickly and rendering believable light, material, and movement, teams help clients see trade-offs clearly. Virtual walkthroughs reveal how a new opening brightens a lobby or how shifting a stair saves headroom downstream. Commentary from maintenance staff, users, and neighbors joins early, translating preferences into measurable choices. With visual clarity and data-backed comparisons, approvals arrive faster and later changes diminish dramatically, saving weeks of churn.

Coordinating the Invisible: Services, Structure, and Space

Behind every elegant finish lies a choreography of ducts, pipes, cables, trays, and supports contending for tight ceiling voids. Coordination turns potential conflict into orderly collaboration. By aggregating discipline models, running clash rulesets, and routing services strategically, teams protect spatial quality without sacrificing performance. Issue trackers assign ownership, deadlines, and evidence so problems move, not stagnate. The result is calm site work, fewer frantic calls, and a reputation for reliability that clients notice and recommend generously.

Time and Money, Modeled Together

Scheduling and cost cease being distant spreadsheets when linked directly to geometry. Phasing sequences visualize site logistics, access routes, and decanting strategies for live buildings. Quantities drive budgets from the same source controlling drawings, tightening estimates as design matures. Lead times surface visibly, steering design choices toward available components. With 4D and 5D alignment, everyone witnesses the impact of a change before committing. The organization saves not only cash, but also months of avoidable friction and delay.

Phasing the Live Building Carefully

Renovations often keep occupants in place. Animated sequences show how barriers, temporary wayfinding, and dust control evolve each week, minimizing disruption while maintaining safety. By rehearsing logistics digitally, teams identify clashes between deliveries and exam schedules or quiet hours. Elevator bookings, crane swings, and material laydown align with reality. Facilities managers contribute operational constraints early, and occupants appreciate transparent planning. Trust grows when a plan anticipates daily life rather than bulldozing through it with optimistic assumptions and apologies.

Quantity Takeoffs You Can Trust

Model-based quantities standardize measurement rules and expose assumptions immediately. A shared classification system keeps continuity between design options, procurement packages, and as-built reporting. When geometry changes, budgets update, preventing cost drift that surprises leadership late. Estimators annotate model views with risk notes, alternates, and allowances, bringing nuance into numbers. Weekly snapshots record baselines, enabling clear conversations about value. Confidence in quantities reduces padding, sharpens bids, and rewards proactive collaboration. Precision becomes cultural, not just technical.

Procurement and Lead Times in the Model

Linking components to supplier catalogs and delivery timelines turns models into living procurement planners. When a preferred air handling unit faces a twelve-week delay, the visual schedule makes its ripple effects obvious. Teams preempt stockouts, secure alternates, or resequence tasks smartly. Fabricators receive data-rich outputs early, avoiding rework. With costs, logistics, and availability visible in the same environment, choices become pragmatic rather than aspirational. The project gains resilience against supply turbulence that once derailed even the best intentions.

Field Execution with Data in Every Pocket

On site, clarity wins. Mobile access to coordinated models, drawings, and checklists keeps craftspeople and supervisors synchronized without paper floods. QR codes link objects to details, approvals, and issues. Augmented overlays verify placement before drilling. Field photos, voice notes, and markups loop back instantly, making feedback meaningful. Closeout documentation grows organically rather than frantically at the end. When people trust what they see, quality rises, stress falls, and productivity accelerates with fewer costly do-overs haunting evenings.

RFIs, Issues, and Decisions That Don’t Go Missing

Instead of emails buried in threads, questions become trackable items tied to precise locations, elements, and viewpoints. Assignees, due dates, and status indicators keep momentum visible. Small clarifications get answered in hours, not weeks. Photos and short screen recordings help context land quickly. When leadership reviews dashboards, attention goes to the true blockers. The site breathes easier, and relationships improve because promises are visible, met, and remembered. Invite the team to contribute openly, and celebrate fast, thoughtful decisions.

Quality Closeouts That Stand Up to Scrutiny

Digital checklists aligned with codes and specifications transform inspections into repeatable, auditable routines. Each checklist item anchors to an element with photos, signatures, and timestamps. Defects become clear tasks with accountable owners. As areas hit completion, evidence accumulates for handover automatically. Nobody scrambles to assemble binders during the final week. Clients see transparency, not excuses. The entire team learns from patterns of defects to prevent recurrences. Quality becomes visible, measurable, and worthy of pride rather than paperwork dread.

Handing Over a Living Asset, Not a Binder

The end of construction is the beginning of use. Delivering clean, searchable data—equipment tags, warranties, maintenance schedules, and performance history—empowers facility teams to manage assets confidently. As-built models reflect real installations, not hopeful sketches. Standards like COBie prevent information from scattering across inboxes. When operators inherit clarity, response times shrink, energy use improves, and downtime drops. The building becomes understandable, maintainable, and adaptable, with insights flowing back to inform the next project and community of practice.

All Rights Reserved.